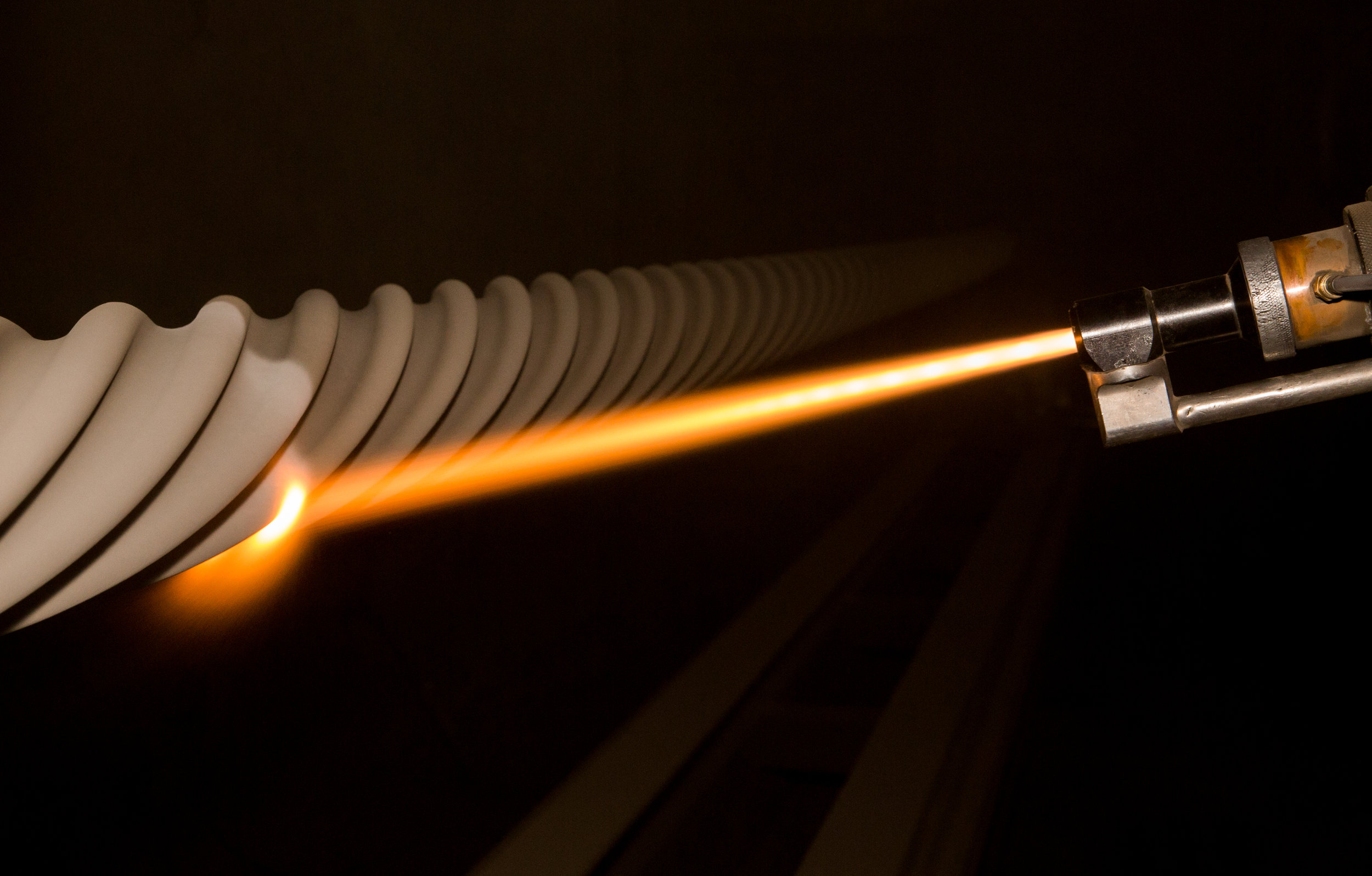

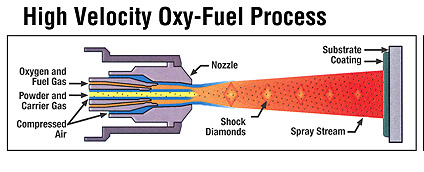

Our Thermal Spray Coatings Use HVOF (High Velocity Oxygen Fuel)

This process produces a high-quality, extremely dense coating that allows for excellent wear protection. It takes many variations of powders to achieve the properties our customers require for their coating needs, and our application utilizes industry-leading equipment.

We use Tafa JP spray systems, an industry-proven product that offers dependable, repeatable, and reliable spray coatings. We currently use TAFA JP 8000 and JP 5000 systems, which are versatile for many industrial applications across the globe. Our thermal spray department has two separate soundproof booths capable of coating small and large components up to 30’ in length.

Industrial Applications

Mixing Rotors

Concrete Pumps

PDM and PCP Rotors

Drilling Tools

Hydraulic Cylinders, Pistons, and Rods

Rolls, Molds, Dies, and Other Forming Surfaces

Press Punches & Tooling

Mining & Agriculture Equipment

Shafts / Rotors for Pump Applications

Components Used in Textiles & Printing

BOP Equipment

Top Drive Equipment

Rotating Equipment

Valves

Characteristics

High Wear Resistance

High Bond Strength

Low Porosity (>1%)

Good Corrosion Resistance

Low Residual Stress